2023年3月1日 Accurate model performance was obtained using Back Propagation Neural Network (BPNN) and Adaptive Neuro Fuzzy Inference System to predict cement Blaine

More

2015年3月10日 The energy savings of the vertical roller mill decrease for marble and hematite with increasing surface from about 62% at 2000 Blaine and 3400 Blaine

More

Contribute to legaojm/m development by creating an account on GitHub.

More

2021年1月29日 In recent years vertical roller mill (VRM) has proved to be a popular choice for finished cement grinding due to low power consumption but it is also very

More

2022年7月5日 The required product fineness is varying from very coarse products (top size 500 µm) to products with very high Blaine figures (10000 cm²/g and more) or d 50 values

More

2021年6月7日 A Blaine number is the surface area-based parameter that is quantified with the use of the air permeability method. The technique is well-established in the cement

More

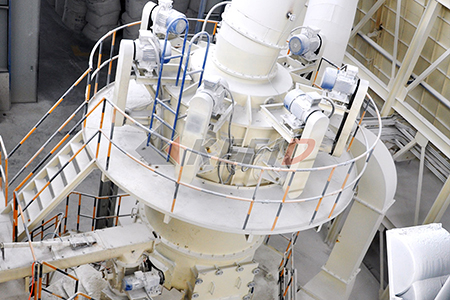

2013年3月1日 Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements.

More

In the first step, the grinding time required to reach the Blaine number of the investigated Cement type (S-OPC: Studied Ordinary Portland Cement) was obtained as 69.75 minutes by kinetic grinding tests.

More

2015年10月23日 Vertical roller mills have a lower specific energy consumption than tumbling mills and require less space per unit and capacity at lower investment costs. Vertical roller mills are developed

More

In order to address grinding efficiency (defined as the increase in mass specific surface vs. net specific energy input) the energy consumption of two pilot scale vertical roller mills (200 mm and 670 mm table

More